Update

Here’s an update on some of the parts I’ve been collecting for the winter rebuild.

A box full from AutoVaux including a VXR/Z20LEH oil pump and gasket, a new 8v sump gasket/baffle, z20let head gasket and various oil seals.

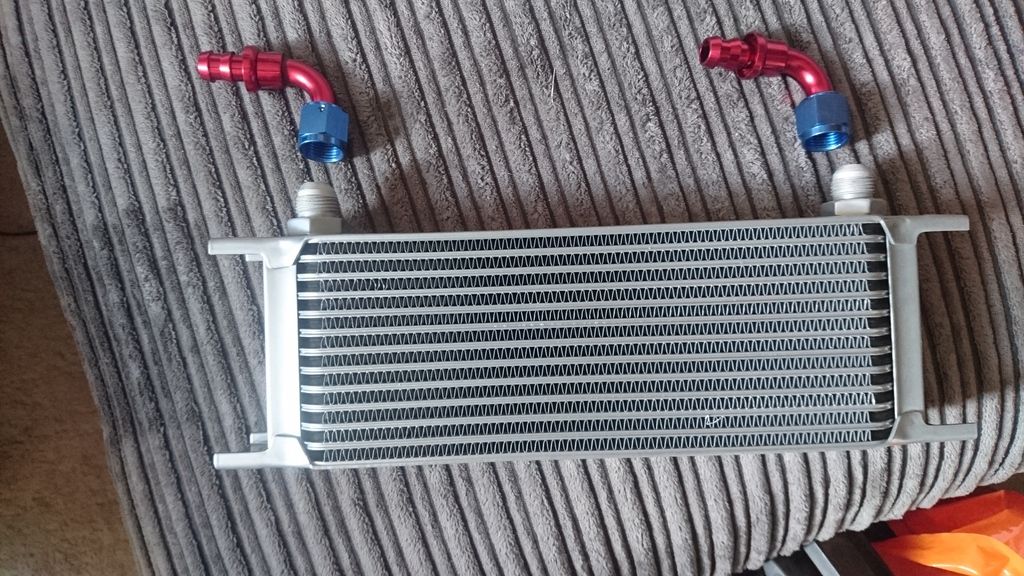

Have also bought some Omega 87mm pistons, a 13 row oil cooler, 875cc Deka injectors to replace my 630cc’s and a 90mm MAF housing.

Only parts left to get before I can build it back up is the modified pick up pipe for the vxr oil pump, some new big and mains bearing shells and then a bigger turbo to the td05 I currently have.

I’m still awaiting to take my block and crank up to phillip for the rebore and crank regrind, I’ve had another non car related project on the go that’s taken funds away from this unfortunately.

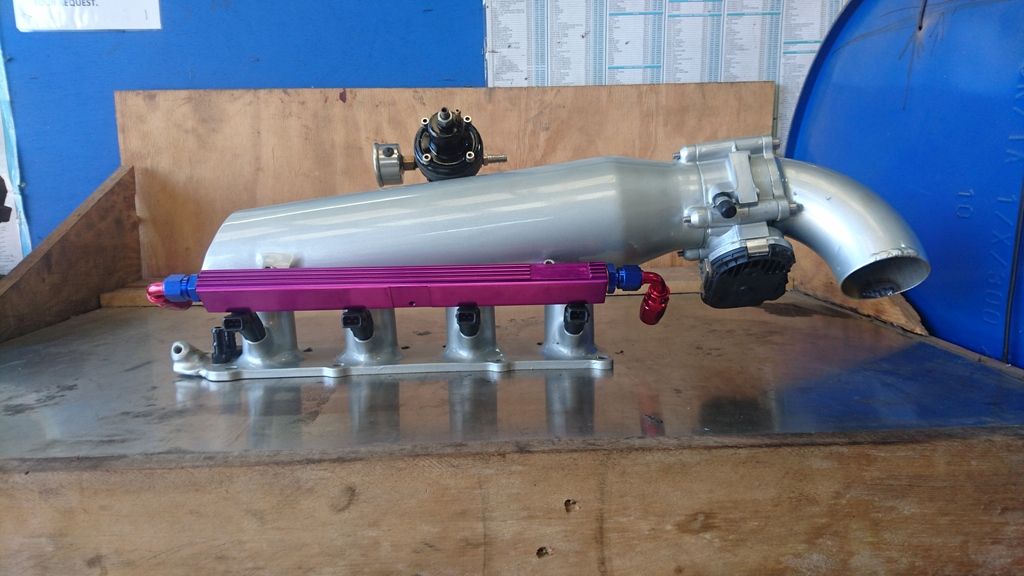

I’ve been tinkering with an inlet manifold that I’ve been making over the past couple of months which will replace my standard item, hoping it should free up a few more HP along the way.

I started out with buying a steel flange and making various calculations and lists with items I needed to build my own inlet, I would love an aluminium item but with the cost of them being 3-4 times more than this tallied up, it was a no brainer. Plus if I want to add anything I can break out the mig and crack on, with out paying somebody else for the pleasure. OK, weight is an issue but meh.

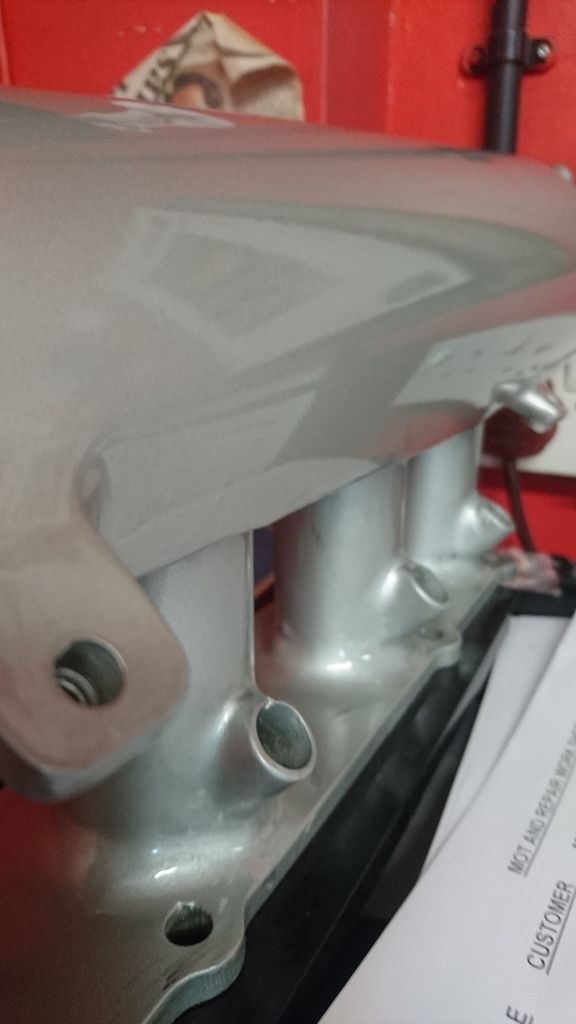

The flange came with a pre drilled hole for the return from the head but it didn’t have the water way from the inlet to the head, after reading a few threads with custom inlets it was recommended to add the 2nd water way to the flange.

I sourced some 45mm stainless tube for the runners, which I then squeezed the one end to make it oval so it sat nicely on the flange.

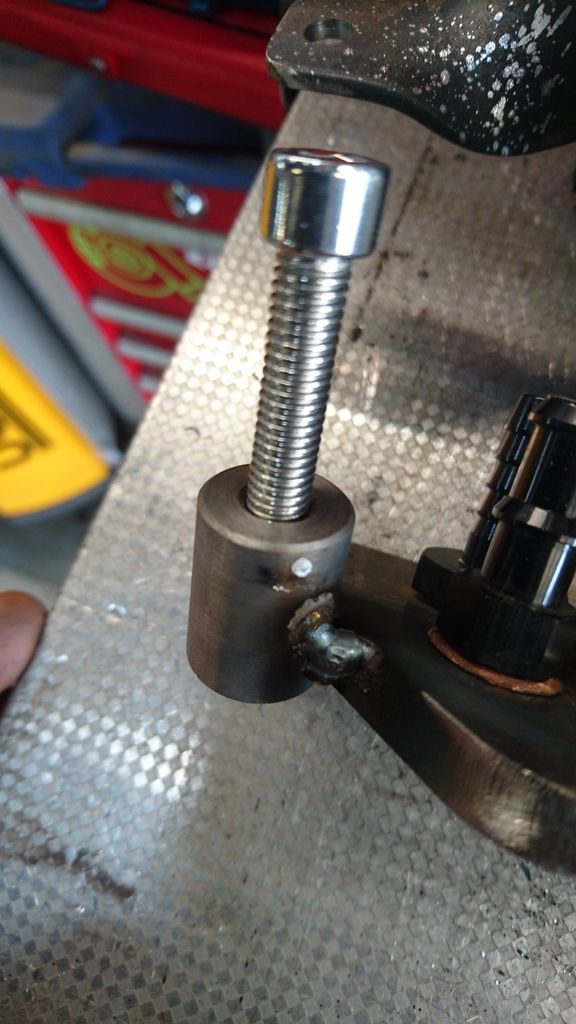

A small length of 18mm outer diameter with a 12mm inner was bought so I could make my own injector bungs. I couldn’t find any pre-made bungs in steel in this country and they weren’t exactly hard to make. The injectors are 14mm, ‘o’ rings were around 14.4mm, I found that roughly 13.75mm hole was needed to drill them out and for the injectors to sit in snugly.

Evo billet fuel rail, these accept 11mm injectors, so again this had to be drilled out for the 14mm injectors.

The bungs and runners were tacked down onto the flange with a trial fit of the plenum.

Clamping the flange down to some good thick flat steel, I welded all the way around the runners. It may not be pretty, but I’m hoping it seals.

Reply With Quote

Reply With Quote