Here's my attempt.

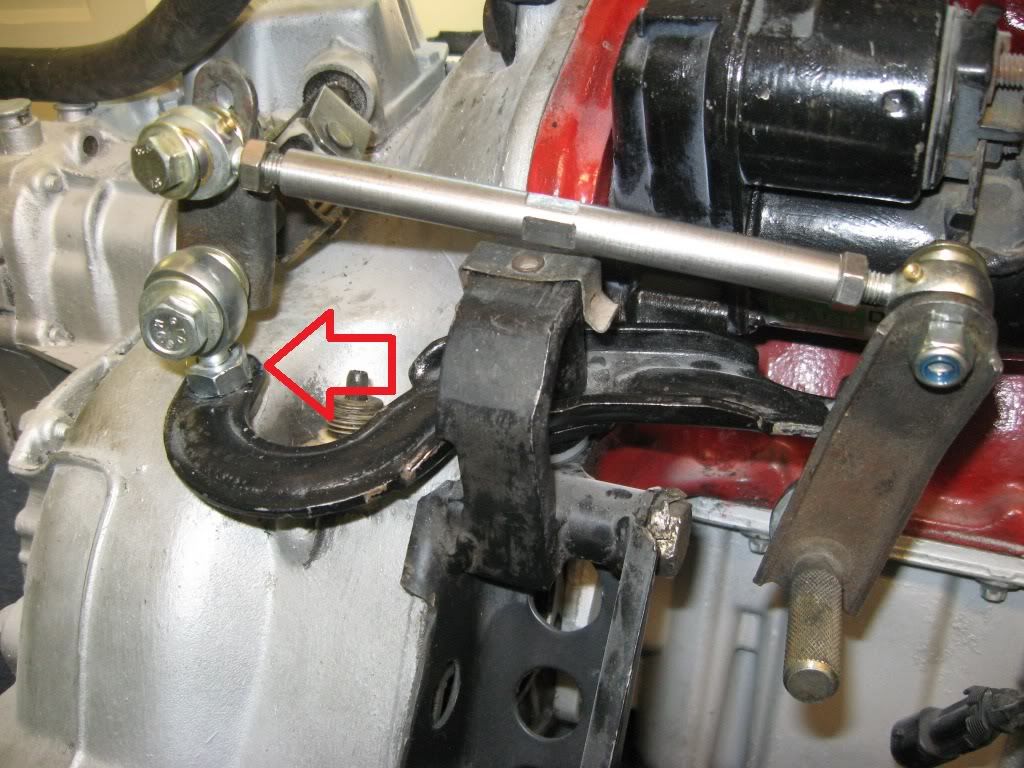

Opted for male rose joints and used a piece of stainless bar I had lying around. Plonked it in my thread and with left and right handed a M10 tap and a couple off flats milled on so its not adjustable in situ, I've since changed the bolts for slightly longer ones. Also replaced the bushes with nylon ones that i machined up. let me know if anyone requires any.

Reply With Quote

Reply With Quote

is true to his word very good and quick at replying posting etc. thanks for my linkage.

is true to his word very good and quick at replying posting etc. thanks for my linkage.