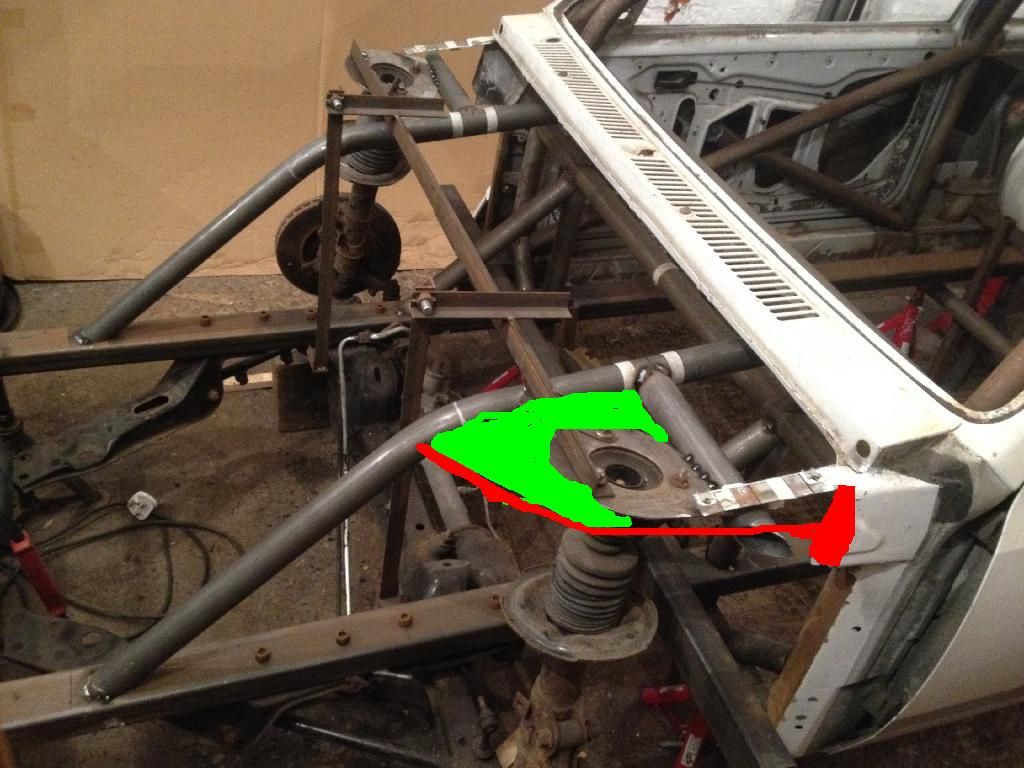

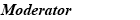

For me the lower dash bar is what confuses the whole thing so much, theres simply no need for it. With that in mind this is probably a sort of route I would go

.

I think you could adapt bars 1,2,3 into your design quite successfully though. I'll have another look at how i would do it with the two dash bars when Im not supposed to be asleep

Reply With Quote

Reply With Quote